Original

Amida (Amitabha) Triad and Two Priests, Made by hammering copper plates

Asuka period, 7th century (Important Cultural Property)

The original work will be on display in room 2 of The Gallery of Horyuji Treasures from April 25, 2023–April 20, 2025.

1. Wax Model

The cast bronze models used for producing repousse images are thought to have been cast using the wax model method. Relief images of the Buddhist deities and the pedestal are molded in beeswax on a base made of the same material.

2. Cast Bronze Model

The wax model is covered with clay. The clay is heated to melt the wax model, which leaves a clay mold with a hollow imprint of the wax model. Molted bronze is poured into the clay mold to fill the cavity, and once the metal has cooled sufficiently, the mold is removed. The surface of the bronze model is then smoothed using chisels.

3. Preparation of Sheet Bronze

Until the end of the Edo period(1603–1868) sheet bronze was producing by hammering a block of bronze, which was cast using a method called Yudoko casting. The resulting bronze block is beaten with an iron hammer until it becomes a sheet with the desired thickness (about 0.4mm in this case). The bronze is heated occasionally to soften it while hammering.

4. Hammering

A bronze sheet is placed over the model and hammered into the shape of the relief image. First, the outline of the central figure is shaped using a wooden hammer followed by the other figures. Then the sheet is heated to soften it and details are formed using wooden and bamboo punches. The sheet becomes thinner with hammering, therefore taking care not to break it, it is punched repeatedly from various directions to make the outline of figures clear.

5. Further Hammering

Next, the further details, such as the robe folds, mandorla, and patterns on the pedestals, are shaped. First, the details are shaped roughly using a smaller size bamboo punch. Then clear lines of the patterns are formed by punching with an antler punch along the line model. Careful attention is required not to create wrinkles on the convex surfaces, such as the lotus petals.

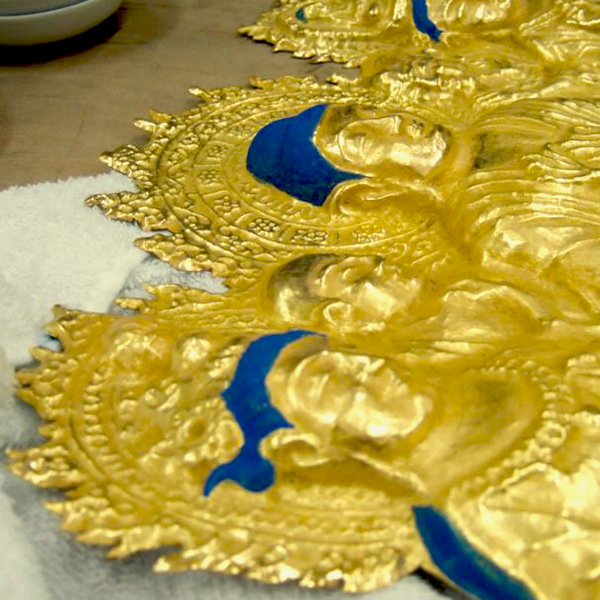

6. Cutting Edges, Gilding and Coloring

The edges of the sheet are cut off along the model edges using a metal chisel. Gold amalgam (a mixture of mercury and gold) is painted on the repousse surface. The hair and mouths are colored in blue and red respectively using mineral pigments mixed with animal glue. And the eyelid outlines, irises, eyebrows, and beard are painted in ink.